According to Hearing Industries Association (HIA), 3,969,895 hearing aids were sold in the United States during 2018. This is a 5.3% increase from the year before and it falls 30,000 units short of 4 million. The amount of hearing aids being sold annually is constantly increasing each year. As someone who is part of the Deaf & Hard of Hearing (HH) community, I find these statistics very interesting considering how expensive hearing aids actually are. Hearing aids can range anywhere between a very low $1,000 and all the way up to $6,000. But when someone has lost their hearing, they are normally losing it in both ears so they would need two hearing aids. This means that the cost is anywhere from $2,000 to $12,000. As I continued to think about it, I was questioning what actually goes into the making of hearing aids.

The Footprint

There are 8 major steps to the manufacturing process of creating a hearing aid and they are; Data entry, vacuum form of impression, casting of finished impression, creating the shell, building the hearing aid into the shell, creating the microminiature circuits, assembling the electronic hardware and sealing and finishing. Then there is the quality control and testing of the product. But before all of that can happen there has to be the testing. This testing is done by a trained professional, usually an audiologist, and the test consist of routine hearing tests covering a variety of parameters. After the hearing tests comes the impression or mold of the outer ear. Since every ear is different, each hearing aid is custom to the user. Once these steps are complete, the manufacturing process begins.

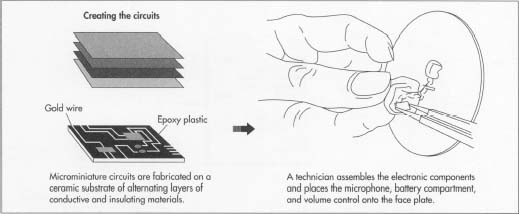

First is the data entry, which is just entering all of the data that was taken during the hearing test and a computer is able to figure out the correct type of hearing aid that is needed, the levels of amplification and the electronic circuitry that needs to be used. After this comes the vacuum form of impression. This part uses a sheet of clear vinyl and heat that is placed over the impression to create a reverse of it. Then after it cools, it’s dipped in hot wax. Once dried, it’s time to move onto the cast of finished impression. During this process, metal places/rings and rubbery silicone is used to make the final impression. Once created, the shell or outer casting is created using mix liquid acrylic of equal parts monomer and polymer with the mold. After cooling, a perfect replica should be formed of the impression. Next comes the building of the hearing aid into the shell. A small piece of silicon wire is run through the shell to allow holes to be drilled into the shell and the shell is buffed, smoothed and shined to finish. Then the microminiature circuit is created. As you can see in the image below, the circuits and components are created on conducting layer of gold and silver and the insulating layers contain silicon compounds and once everything is finished they are sealed in an epoxy paste and heat-hardened.

Once steps 1-6 are finished, step 7 begins which is assembling the electronic hardware. The microphone, amplifier, battery compartment and volume control are all hand-wired onto the faceplate where the holes have been drilled. Lastly is sealing and finishing, when everything else is completed the parts are carefully packaged together and are sealed and ready for quality control and testing.

Every hearing aid is custom made so one technician is making it. With this being said, it would make sense that the hearing aids cost so much, but it doesn’t. Most hearing aid parts are only around $100 and assembled in China by children, yet they can cost around $2,500. This levels a lot of people wondering why these kids are getting paid so low if the profit is so much.

The Impact

The Deaf and Hard of Hearing Community is tremendously impacted by this technology because hearing aids were literally designed for them. Without hearing aids, Deaf and HH people wouldn’t be able to gain a bit of their hearing back. Although hearing aids don’t make you regain your full hearing abilities back, they still give you more than you would be able to on your own. Since there are many different levels of hearing loss, whether your Deaf or HH, as we learned above, you can get hearing aids for different levels. The impact of having hearing aids within this community is life changing.

For example, my Grandma was losing her hearing, from old age, to the point where she couldn’t hear birds singing anymore when she sits on her porch in the morning. This was making her extremely depressed because that was one of her favorite things to do during the summer. When she finally decided to get a hearing aid, it gave her that level of hearing back so she could hear the birds. Although it didn’t give her back all of her hearing, it was enough to impact her life in a positive way. This is just one small example of how hearing aids can impact the Deaf and HH.

Although the positives impacts definitely outweigh the negative ones, there are some. Such as the cost of a hearing aid and the fact that most insurance companies don’t cover them. Like I stated above, hearing aids are extremely expensive and are truly no reason besides the fact that they can be. Because they are so expensive, this limits the amount of people who can actually buy them. This is the major downside of this technology. Although they were designed for one specific community in mind, the build companies have also become very greedy with their money. Since our world is a hearing world and if you are Deaf or HH you are going to struggle because the world wasn’t built for you in mind, this means that it’s very important that you have a hearing aid, and the top companies are very aware of this fact. This is why within the cost of a hearing aid, it only takes 8% of the cost for the companies to break even. That means that the 92% left of the money is dispensing fees, administration salaries and profits. The big companies have taken advantage of this community and it preventing people from getting this very important and useful technology.

The Decisions

The overall question is, why are hearing aids are so expensive even though it doesn’t cost as much to make them? And, how can we make them cheaper? Although the first question is more on the big companies to answer, the second question can be decided by both parties, the companies and the user. This topic of lowering the cost of hearing aids is very important for the Deaf and HH community because many people can’t afford it so they can’t receive one or they are put into debt because they need one and buy one. In order to have a decision be made, there needs to be a town hall of some sort. The Deaf and HH community should be there and so should the top hearing aid companies. During this town hall the concerns of the expense of hearing aids and the importance needs to be expressed to the companies. And the companies need to explain why they are charging so much. They need to explain the first question of why are hearing aids are so expensive even though it doesn’t cost as much to make them? After hearing both sides of this, a decision should be made as to lower the cost or to find some other way to make the hearing aids available to those who can’t afford it. This way both sides are understanding each others concerns and thoughts and a mutual decision can be made.

References

http://www.madehow.com/Volume-2/Hearing-Aid.html

https://www.healthyhearing.com/report/52623-What-goes-into-the-cost-of-hearing-aids

http://www.hearingreview.com/2019/01/us-hearing-aid-sales-increase-5-3-2018-approaches-4-million-unit-mark/

https://www.hearing.org/

You must be logged in to post a comment.